Two-phase flow in complex geometries

A shell-and-tube type heat exchanger is used widely in various industrial plants. The performance of heat exchanger is influenced by the geometry and arrangement of heat transfer tubes. In some heat exchangers, boiling occurs outside the heat exchanger tubes. Consequently, the structure of gas-liquid two-phase flow in complicated geometry should be understood sufficiently to achieve the optimum design. There exist various candidates for the configuration of heat transfer tubes. However, a number of experiments are required to select the design that provides the best performance. It would hence be advantageous if promising candidates can be deduced from numerical simulation. In view of this, simple air-water experiments and multi-dimensional numerical simulations of two-phase flow in complicated geometries have been carried out to develop the reliable numerical model to estimate the performance of heat exchangers.

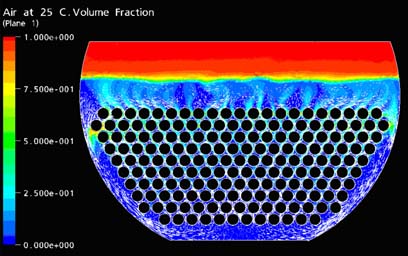

Flow structure in a shell-and-tube heat exchanger